The wire feeder is driven by a motor that draws its’ power from the power source. The wire feeding arrangement pulls wire from the spool mounted on the reel, and feeds it to the welding gun. DCEP is more commonly used for gas-shielded FCAW process.

Both DCEP (direct current electrode positive) and DCEN (direct current electrode negative) polarities are used. Also, such power sources require more maintenance.įCAW machines generally use direct current. But since many moving parts feature on the machine, the operation is noisier, is uneconomical, besides the polluting nature of the IC engine. These machines provide a more stable arc.

The power is generated by an internal combustion engine driven by diesel or gasoline.

Eagle arc flux cored wire generator#

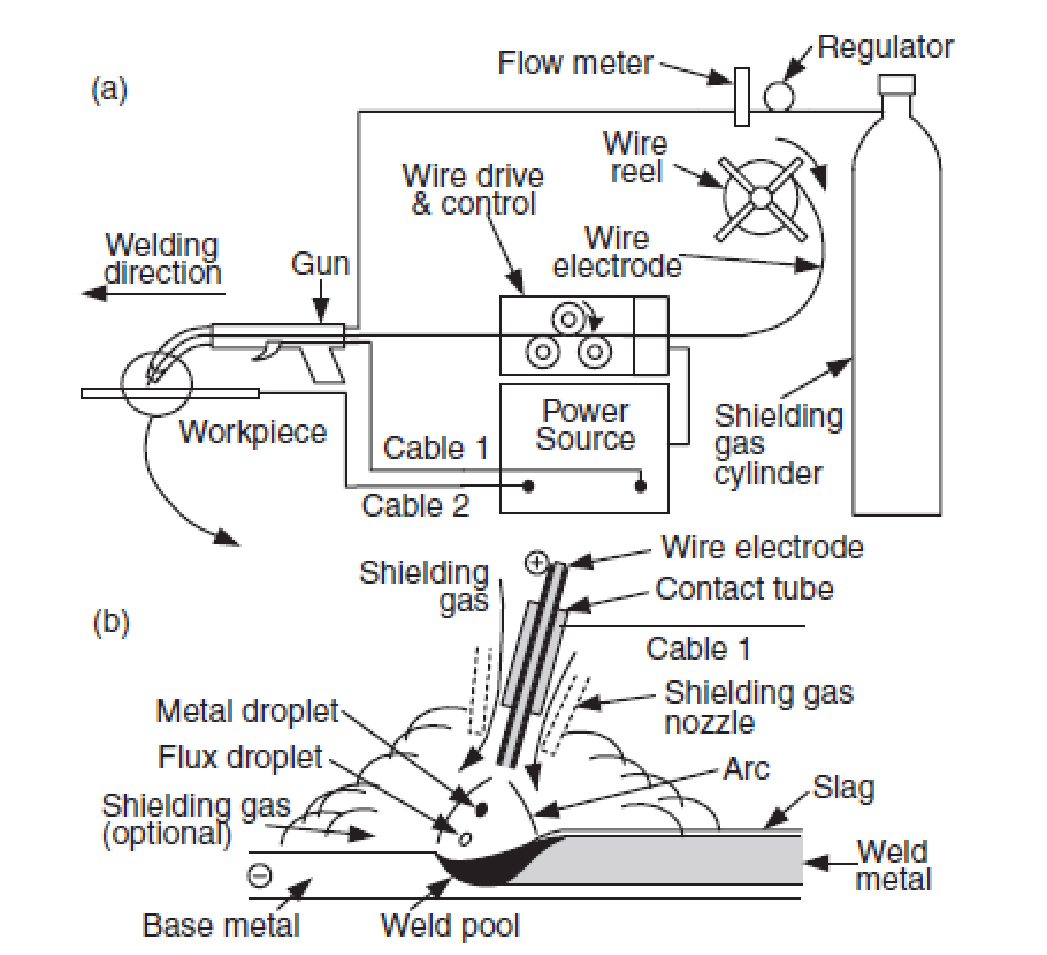

The generator type is generally used for field use. Both transformer-rectifier and generator type of power sources are used. Power sources of direct current constant voltage type are generally recommended for FCAW. Other than this, there isn’t much that separates the power source of a gmaw machine and fcaw machine. This is because fcaw is sometimes done with higher welding currents. The ampere rating of FCAW power sources is generally higher than that of GMAW power sources. This means that the machine can weld continuously for every 6 minutes out of 10. Most machines come with a duty cycle of 60%. The duty cycle varies from brand to brand. The power source may operate on a single phase input or a three phase input, with the frequency of the supply being 50 hertz or 60 hertz. An ammeter and voltmeter on the machine display the current and voltage being supplied by the machine. The power source supplies electrical power for welding. This figure is for a semi-automatic mode of welding. The following figure illustrates the layout of the various components in flux-cored arc welding equipment. Many accessories are added in machine welding and automatic welding, such as seam followers, motion devices, etc. The basic equipment in FCAW is as described above. The welding gun is also different when the shielding gas is used. Gas cylinders and additional welding cables to carry the gas are used in this case. When this happens, arrangement for gas shielding also needs to be provided. The main components of the equipment are a power source, wire-feeding arrangement, welding gun, welding cables to carry current from the machine to the gun, and controls for fixing the welding parameters.Īs mentioned above, sometimes a shielding gas is used to supplement the flux shielding. The basic layout of the equipment used in flux-cored arc welding is same as that in gas metal arc welding. This article discusses a few components of FCAW equipment. The overall equipment for FCAW is simple in construction and easy to understand. The wire is continuously fed by a mechanized wire-feeding arrangement in FCAW. The diagram below illustrates the welding action with FCAW process.

Sometimes an externally supplied shielding gas is also used to supplement the flux shielding. The flux provides shielding to the electric arc. However, since flux is involved, some smoke and spatter are generated, and a layer of slag is formed at the top of solidified weld metal, which has to be removed by the welder. Also, at high currents, the arc is more smooth and stable in comparison to when high diameter filler wire is used in GMAW. The presence of flux improves arc action, improves deposition efficiency, bead appearance, and mechanical properties of the weld. It is a tubular electrode, with a metal sheath surrounding a column of flux – throughout the length of the wire. As the name suggests, the flux-cored wire is cored with flux. In fact, the only feature that makes it distinct from the GMAW is the flux-cored wire that is used as the filler as well as electrode. Flux-cored arc welding is a variation of gas metal arc welding (GMAW).

0 kommentar(er)

0 kommentar(er)